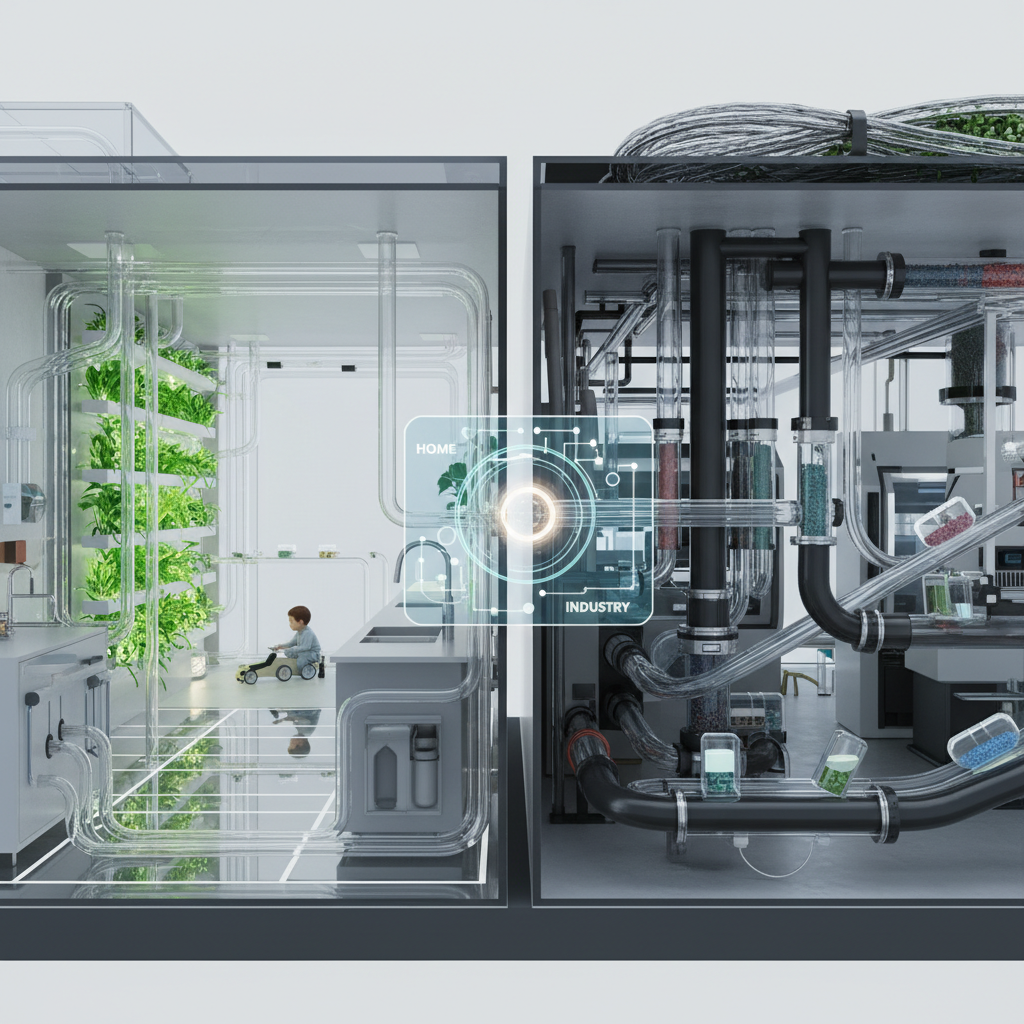

Top 10 Uses of Plastic Tube in 2025 for Home and Industry

In the ever-evolving landscape of materials, plastic tubes have emerged as versatile components essential for both domestic and industrial applications. As we look ahead to 2025, innovations in the plastic tube industry are set to reshape how we utilize these indispensable items in our daily lives and workplaces. According to Dr. Emily Carter, a leading expert in polymer science, "Plastic tubes are not just functional; they embody the essence of adaptability, catering to a vast range of needs across various sectors."

From plumbing and irrigation systems to packaging solutions and medical applications, the potential uses of plastic tubes are boundless. Their durability, lightweight nature, and resistance to corrosion make them ideal for a multitude of scenarios. As we delve into the top ten uses of plastic tubes anticipated for 2025, we will explore how these simple yet effective tools can improve efficiency and sustainability in both home and industry settings. The ongoing developments in materials science promise to enhance the performance characteristics of plastic tubes, propelling them into new realms of utility and innovation.

Emerging Applications of Plastic Tubes in Sustainable Packaging Solutions for 2025

The increasing focus on sustainability in packaging solutions is driving the innovation and use of plastic tubes in both home and industrial applications. In 2025, plastic tubes are expected to play a significant role in eco-friendly food packaging, providing a versatile and efficient method to reduce waste. With the global eco-friendly food packaging market projected to reach USD 353.78 billion by 2030, the demand for sustainable materials is greater than ever, paving the way for innovations such as cellulose-based packaging. These new alternatives not only minimize environmental impact but also effectively replace traditional plastic without compromising functionality.

Moreover, the organic shift towards fiber-based packaging for cosmetic products like lip balm exemplifies the industry's commitment to reducing plastic pollution. The emergence of such solutions highlights a growing trend where packaging is designed not just for protection, but also to enhance sustainability and recyclability. As industries adapt to meet consumer demand for greener options, plastic tubes will likely evolve to incorporate more sustainable materials and design practices, fulfilling the critical balance between performance and environmental responsibility.

Innovative Uses of Plastic Tubes in Automation and Manufacturing Industries by 2025

Plastic tubes are poised to revolutionize both home and industrial applications by 2025, particularly in the fields of automation and manufacturing. With advancements in materials science, plastic tubes are becoming lighter, more durable, and resistant to various chemicals, making them ideal for a range of uses. In automated manufacturing systems, plastic tubes can be utilized for conveying materials, ensuring that production flows smoothly and efficiently. Their flexibility and adaptability allow for custom configurations that can easily accommodate complex machinery layouts, reducing downtime and enhancing overall productivity.

In addition to their mechanical roles, plastic tubes are increasingly being integrated into smart technology solutions in industries. For instance, within the realm of IoT (Internet of Things), plastic tubes can be embedded with sensors to monitor fluid transport systems in real-time, providing critical data that can help prevent malfunctions and optimize operations. Moreover, the lightweight nature of plastic tubing is facilitating innovations in robotics, where they can be employed in articulating structures, enhancing mobility and functionality in automated processes. With these innovative applications, plastic tubes are set to play a crucial role in the evolving landscape of automation and manufacturing by 2025.

Top 10 Uses of Plastic Tube in 2025

Impact of Plastic Tube Design on Efficiency in Agriculture and Horticulture in 2025

In 2025, the design of plastic tubes is set to revolutionize efficiency in agriculture and horticulture, driven by both technological advances and sustainability goals. According to a report by MarketsandMarkets, the global agricultural plastic market is expected to reach $14.25 billion by 2025, with plastic tubes playing a pivotal role in irrigation systems and nutrient delivery. The lightweight, durable nature of plastic tubes allows for more efficient water distribution, reducing waste by up to 30%. Their flexibility and resistance to corrosion make them ideal for a variety of agricultural applications, from drip irrigation systems to hydroponics.

Innovative designs are also enhancing the functionality of plastic tubes in horticulture. A study published in the Journal of Agricultural Science highlighted that advanced plastic tube designs improve airflow and water retention in soil, promoting healthier plant growth. By integrating smart sensors within these tubes, farmers can monitor moisture levels in real time, allowing for precise irrigation and reducing water usage by as much as 40%. As these technologies become more widespread, the impact of plastic tube design will significantly contribute to sustainable practices in both home gardens and large-scale agricultural operations.

Advancements in Medical Technology: Plastic Tubes in Healthcare Applications for 2025

In 2025, the integration of plastic tubes in healthcare applications will showcase significant advancements driven by both technological innovations and market demand. The physiological saline market is projected to reach USD 10.2 billion, growing at a compound annual growth rate (CAGR) of 6.2% from 2025 to 2035. This surge highlights the critical role of plastic tubes in medical settings, particularly in IV administration and fluid management, where both reusable and single-use options are essential for maintaining hygiene and patient safety.

Moreover, the medical fluoropolymers market is expected to escalate to USD 1.5 billion, with a notable CAGR of 9.6% in the same period. These materials are particularly valuable for creating durable, chemical-resistant plastic tubes that can withstand rigorous medical environments. As the healthcare sector prioritizes advanced medical devices and efficient delivery systems, the reliance on high-performance plastic tubes will inevitably rise, aligning with broader trends in medical device innovation and patient care advancements.

The Role of Plastic Tubes in Smart Home Technologies and IoT Devices by 2025

As we move towards 2025, plastic tubes will play a pivotal role in the expansion of smart home technologies and the Internet of Things (IoT) devices. According to a report by Allied Market Research, the global IoT market is expected to reach $1.1 trillion by 2026, with smart home devices making up a significant portion of this growth. Plastic tubes are integral for housing wiring, plumbing, and even air ducts within smart home systems, allowing for efficient management of utilities while ensuring flexibility and durability.

Moreover, the customization capabilities of plastic tubing lend themselves well to innovative designs in health monitoring and smart appliances. Data from Markets and Markets indicates that the smart home market will grow from $79.16 billion in 2020 to over $135 billion by 2025. This impressive growth trajectory highlights the demand for lightweight, efficient, and eco-friendly materials like plastic. As smart home devices increasingly integrate functionalities such as temperature control, lighting, and security systems, plastic tubes will be crucial for facilitating seamless connectivity and operation, supporting the intricate mesh of IoT networks.

Top 10 Uses of Plastic Tube in 2025 for Home and Industry

| Use Case | Description | Applications | Benefits |

|---|---|---|---|

| Smart Irrigation Systems | Used for delivering water efficiently to plants and crops. | Agricultural fields, gardens, and landscaping. | Water conservation, automation, and reduced labor costs. |

| HVAC Systems | Ventilation, heating, and air conditioning ducts. | Commercial buildings, residential homes. | Improved air quality, energy efficiency. |

| Healthcare Applications | Medical tubing for various treatments. | Hospitals, clinics, and home healthcare. | Sterility, safety, and easy handling. |

| IoT Sensors | Conduits for wiring and protection of sensors. | Smart homes, industrial automation. | Durability, flexibility, and ease of installation. |

| Electrical Wiring Insulation | Protective covering for electrical wires. | Residential and industrial electrical systems. | Safety, longevity, and reduced fire risk. |

| Food and Beverage Packaging | Containers and conduits for food transport. | Food production and distribution. | Reduced spoilage, convenience, and hygiene. |

| Aquaponics Systems | Water circulation and nutrient delivery. | Urban farming, sustainable agriculture. | Resource efficiency, increased yield. |

| 3D Printing Applications | Filament for creating various prototypes and models. | Manufacturing and prototyping sectors. | Customization, on-demand production. |

| Home Automation | Tubes for smart home devices communications. | Smart lighting, heating, and security systems. | Enhanced convenience, increased security. |

| Telecommunications | Support and protection for fiber optic cables. | Internet services, television, and telephone networks. | Reliability, insulation against environmental factors. |

Related Posts

-

Troubleshooting Issues with Plastic Tubes with Caps: What Global Buyers Need to Know

-

Challenges with Storing and Transporting Small Plastic Containers

-

The Rise of Eco-Friendly Plastic Clamshell Containers: Trends and Benefits Backed by 2023 Data

-

7 Proven Tips to Choose the Best Clear Plastic Containers for Your Needs

-

7 Innovative Ways to Use Clear Plastic Boxes for Every Room in Your Home

-

What are the Benefits of Using Plastic Containers in Everyday Life