5 Essential Tips for Choosing the Right Clear Plastic Tube for Your Project

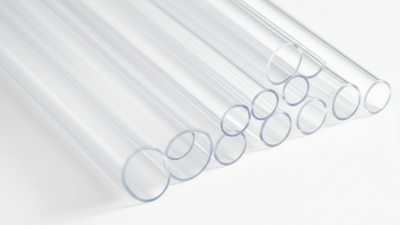

When it comes to selecting materials for various projects, the choice of the right clear plastic tube can significantly impact functionality, aesthetics, and overall project success. According to a report by MarketsandMarkets, the global plastic tubing market is projected to reach $20 billion by 2025, driven by the increasing demand across industries such as healthcare, packaging, and construction. Clear plastic tubes, in particular, offer versatility and clarity, making them a preferred choice for both practical and decorative applications. However, with numerous options available in terms of size, material, and design, making the right selection can be daunting. In this blog, we will explore five essential tips to help you choose the perfect clear plastic tube for your specific needs, ensuring optimal performance and satisfaction in your project outcomes.

Understanding Your Project Requirements: Key Factors to Consider

When selecting a clear plastic tube for your project, understanding your specific requirements is crucial. Different applications demand different tube qualities, such as flexibility, durability, and resistance to various environmental factors. According to a report by Grand View Research, the global plastic tubing market is expected to reach $10.25 billion by 2025, indicating a growing demand for diverse types of plastic tubes tailored to specific project needs.

Key factors to consider include the tube's chemical resistance, clarity, and dimensions. For instance, if your project involves transporting fluids, selecting a tube with high chemical resistance and clarity is essential to ensure safety and visibility. The Plastics Industry Association highlights that nearly 70% of plastic tubes are used in medical applications, showcasing the importance of choosing the right material that meets the required standards. Moreover, understanding the mechanical properties, such as tensile strength and elongation, can greatly impact the performance of the plastic tube in your project.

5 Essential Tips for Choosing the Right Clear Plastic Tube for Your Project

| Criteria | Description | Importance Level | Examples |

|---|---|---|---|

| Material Type | Choose between acrylic, polycarbonate, and PVC based on strength and clarity. | High | Acrylic for clarity, PVC for cost-effectiveness. |

| Diameter | Ensure the tube diameter fits the intended use and application. | Medium | Small for fluid transfer, larger for structural purposes. |

| Thickness | Select the appropriate wall thickness to ensure durability and flexibility. | High | Thicker for pressure applications, thinner for light-duty use. |

| Temperature Resistance | Consider the temperature range the tube will be exposed to. | Medium | Acrylic is better for low temperatures; polycarbonate for high. |

| Cost | Evaluate your budget against the requirements and material options. | High | PVC is generally more cost-effective than acrylic or polycarbonate. |

Types of Clear Plastic Tubes: Finding the Best Fit for Your Needs

When selecting the right clear plastic tube for your project, understanding the different types available is crucial. Clear plastic tubes come in various materials, including acrylic, PVC, and polycarbonate, each offering distinct advantages. Acrylic tubes are lightweight and provide excellent clarity, making them ideal for display and artistic projects. PVC tubes, on the other hand, are more flexible and often more cost-effective, suitable for applications that require bending or shaping. Polycarbonate tubes boast superior impact resistance, making them the best choice for environments where durability is essential.

Additionally, consider the size and diameter of the tube. Standard sizes are readily available, but customizing your tube might be necessary for specific applications. Larger diameters can accommodate more substantial liquid flow or larger components, while smaller tubes are perfect for lightweight or detailed work. Always assess the clarity level required for your project, especially in applications involving visual aesthetics. With the right type of clear plastic tube matched to your needs, your project can achieve both functionality and appeal.

Evaluating Material Properties: Strength, Flexibility, and Clarity

When selecting the right clear plastic tube for your project, it’s crucial to evaluate the material properties that will directly impact performance. Strength is a primary consideration, especially if the tube will be subjected to pressure or mechanical stress. Look for specific materials like polycarbonate or acrylic, which are known for their exceptional durability and impact resistance. Understanding the tube's strength-to-weight ratio will also ensure that it meets your project’s requirements without adding unnecessary bulk.

In addition to strength, flexibility plays a vital role in the practical application of clear plastic tubes. If your project requires bending or shaping, consider materials that offer high flexibility without sacrificing clarity. Flexible PVC is a popular choice, providing a balance between bendability and transparency. Moreover, clarity is equally important, especially in applications where visibility of the contents is essential. Ensure that the material has a high optical clarity rating to maintain the necessary transparency while also being resilient against scratches and damage. Choosing a tube that excels in these material properties will set a solid foundation for the success of your project.

Sizing It Right: How to Measure and Select Tube Dimensions

When selecting a clear plastic tube for your project, one of the most crucial steps is understanding how to properly measure and select the appropriate dimensions. Start by determining the intended use of the tube, whether it's for storage, fluid transfer, or display purposes. Consider the inner diameter—this is vital for ensuring that the contents can easily flow or fit within the tube without obstruction. For instance, if you're planning to use the tube for liquids, ensure the inner diameter is compatible with the type of liquid and the flow rate you require.

Next, don't overlook the importance of the outer diameter and wall thickness. The outer diameter affects how the tube will fit into your design or assembly. If you're incorporating the tube into existing structures or connectors, measuring accurately is essential. Wall thickness also plays a significant role in durability; thicker walls provide greater strength but may add extra weight. Evaluate the balance between the robustness needed for your application and the flexibility or lightweight properties that might be desirable for ease of handling. By carefully measuring these dimensions, you can select a clear plastic tube that perfectly meets the demands of your project.

Choosing the Right Clear Plastic Tube: Key Dimensions for Your Project

This chart illustrates the standard measurements for selecting the right clear plastic tube dimensions for various projects. Proper sizing helps ensure functionality and compatibility with intended applications.

Budgeting for Quality: Cost Considerations When Choosing Plastic Tubes

When selecting clear plastic tubes for your project, budgeting plays a crucial role in ensuring that you balance quality and cost effectively. While it may be tempting to opt for the cheapest option, investing in higher-quality tubes can save you money in the long run by reducing the need for replacements and minimizing the risk of project failure. Evaluate your project requirements carefully to determine the best price-quality ratio that meets your needs without overspending.

One essential tip is to compare prices from different suppliers while keeping an eye on the quality specifications. Look for detailed product descriptions to understand the material durability and any applicable certifications. Additionally, consider the volume you require; purchasing in bulk can often yield significant savings and provide you with the quality tubes your project deserves.

Don’t overlook the potential long-term costs associated with cheaper options. For instance, low-quality tubes can lead to issues like leaks or breakage, which may incur additional costs. By prioritizing quality within your budget, you will ultimately make a more informed decision that supports your project's success.

Related Posts

-

Troubleshooting Issues with Plastic Tubes with Caps: What Global Buyers Need to Know

-

Global Excellence in Manufacturing Small Plastic Containers A Testament to Chinese Pride and Worldwide Reach

-

5 Innovative Tips for Choosing the Best Clear Packaging Solutions in 2023

-

Exploring Unique Alternatives to Traditional Tube Boxes for Your Packaging Needs

-

What are Kraft Tubes and Their Impact on Sustainable Packaging Solutions

-

10 Essential Tips for Selecting the Best Packing Tubes for Your Global Supply Needs