How to Choose the Best Tube Boxes for Your Products?

Choosing the right tube boxes for your products is crucial in today’s competitive market. According to packaging expert Jordan Lang, “Quality tube boxes can elevate your brand and enhance customer experience.” These boxes not only protect items but also serve as a fundamental part of branding.

When selecting tube boxes, consider their design and functionality. The material should align with the product's needs. For instance, lightweight items may benefit from thinner cardboard, while heavier products require sturdier options. It's essential to balance aesthetics and durability; a beautifully crafted box can grab attention but might not protect its contents as needed.

Reflecting on the selection process, some might overlook practical features like closure types and ease of use. These aspects can greatly influence customer satisfaction. An attractive design is important, yet it should not compromise the box's practical application. Think critically about how well your tube boxes serve both their purpose and your brand's image.

Factors to Consider When Choosing Tube Boxes for Your Products

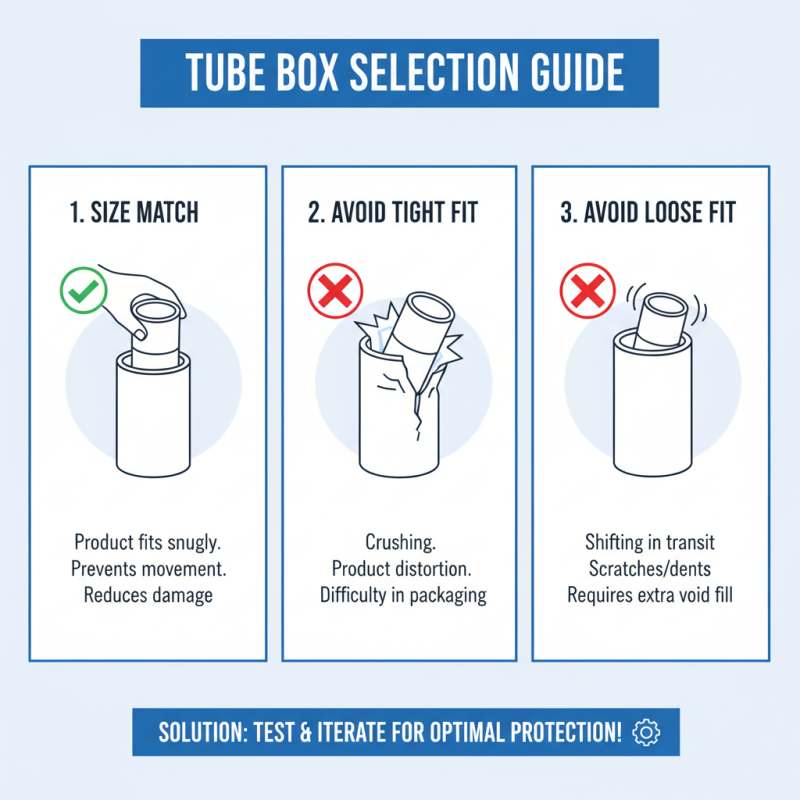

When selecting tube boxes for your products, several factors are essential. The size of the box should match your product dimensions. An overly tight fit can lead to damage. Conversely, a loose fit can cause movement during transit. Achieving the right balance seems simple, yet it often requires testing different sizes.

Material choice significantly impacts durability and aesthetics. Some materials offer better protection but might look less appealing. Others are visually striking but could lack structural integrity. We often overlook material weight, which can affect shipping costs. Don’t ignore this aspect when making your decision.

Design is another vital factor. The appearance of tube boxes can enhance your brand's image. Consider the colors and prints carefully. They should reflect your brand while engaging customers. However, intricate designs might complicate the production process, leading to delays. Balancing creativity and practicality is a challenge worth pondering.

Materials Used in Tube Box Production and Their Benefits

When selecting tube boxes, understanding the materials used in their production is crucial. Common materials include cardboard, paper, and plastic. Each material presents unique benefits. According to a study by Smithers Pira, the global market for packaging is projected to reach $500 billion by 2024. Sustainable packaging is gaining traction, and cardboard is often favored for its recyclability.

Cardboard tube boxes offer durability and lightweight qualities. They can withstand the rigors of transportation without compromising product integrity. Moreover, they are cost-effective, making them a preferred choice among many businesses. In contrast, plastic tubes may provide water resistance but can be less environmentally friendly. Consumers are increasingly aware of the impact of plastic on the environment.

Choosing the right material requires careful consideration. Some businesses may overlook the importance of sustainability. A report by the Ellen MacArthur Foundation indicates that only 14% of plastic packaging is recycled globally. This statistic highlights the need for brands to reflect on their choices. Transitioning to more eco-friendly materials can enhance brand image and appeal to environmentally conscious consumers.

Material Comparison for Tube Box Production

This chart provides a comparison of different materials used in tube box production, showcasing the percentage usage of each material. Cardboard is the most commonly used material due to its balance of durability and cost-effectiveness.

Different Styles and Designs of Tube Boxes Available in the Market

When selecting tube boxes, it’s crucial to explore the different styles and designs available in the market. Tube boxes are versatile and functional packaging options that can cater to various products. In recent years, the packaging industry has seen a surge in the popularity of cylindrical designs. According to a study by Mordor Intelligence, the global packaging market was valued at approximately $500 billion in 2023, illustrating the significance of innovative designs.

There are several styles of tube boxes, including straight wall, tapered, and custom-shaped designs. Straight wall tube boxes offer a classic look, while tapered designs provide a sleek, modern aesthetic. Custom shapes can make products stand out but require careful design consideration. Data from the Packaging Machinery Manufacturers Institute indicates that over 30% of consumers prefer unique packaging, prompting businesses to think outside traditional designs.

However, while focusing on aesthetics, functionality should not be ignored. Packaging that is too elaborate may compromise product safety or increase costs. Balancing beauty and utility is essential for success. Additionally, some manufacturers face challenges in sourcing sustainable materials, which are increasingly demanded by eco-conscious consumers. It’s vital to continuously assess packaging designs to ensure they meet both market trends and consumer expectations.

How to Choose the Best Tube Boxes for Your Products?

| Box Style | Material | Size Options | Design Options | Best For |

|---|---|---|---|---|

| Round Tube Boxes | Cardboard | Small to Large Sizes | Custom Print & Color | Cosmetics, Food Products |

| Square Tube Boxes | Kraft Paper | Variable Sizes | Simple Labels | Gift Items, Crafts |

| Petite Tube Boxes | Recycled Paper | Mini Sizes | Whimsical Designs | Candies, Small Gifts |

| Luxury Tube Boxes | Rigid Board | Custom Sizes | Foil Stamping, Embossing | High-End Products |

Evaluating the Size and Capacity Requirements for Tube Boxes

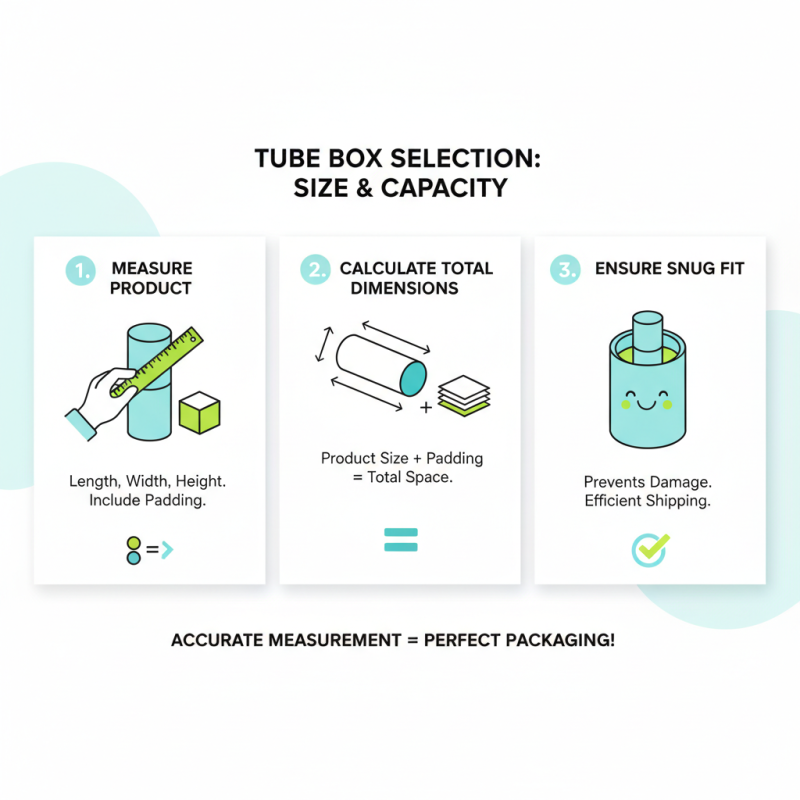

When selecting tube boxes, size and capacity are crucial. Measuring your product accurately is the first step. Think about its dimensions—length, width, and height. Do not forget to include any additional packaging materials, like padding. This calculation helps ensure a snug fit.

Tips: Always allow a little extra space for easy insertion and removal. A perfectly tight box can lead to damage. Conversely, too much empty space can cause items to shift during transit.

If your products vary in size, consider a range of tube boxes. This approach accommodates future needs. Also, remember that a box that’s too large might look unprofessional. It may also impact shipping costs.

Tips: Test the boxes with actual products. Walls should be thick enough to protect but not so thick that they add unnecessary weight. Balancing strength and weight is often overlooked but essential.

Cost Considerations and Budgeting for Tube Box Purchases

When budgeting for tube boxes, understanding true costs is essential.

Tube boxes vary in price based on material, size, and design complexity. According to a 2022 report by Smithers Pira, the global market for tube packaging is expected to grow by 4.1% annually, indicating rising demand. This growth can lead to increased production costs.

Choosing the right supplier can also impact your budget. Some suppliers might offer lower prices but compromise on quality. It’s crucial to balance cost and quality. Research indicates that 70% of customers are willing to pay more for better packaging. This means investing in high-quality tube boxes might enhance brand reputation.

Shipping costs can add another layer of complexity. Tube boxes can be bulky, leading to higher shipping fees. Consider local suppliers to reduce these expenses. However, getting quotes from several suppliers can be time-consuming. Do not be surprised if unexpected costs arise during the purchasing process. Budgeting for those unforeseen expenses can make a big difference in overall costs.

Related Posts

-

Exploring Unique Alternatives to Traditional Tube Boxes for Your Packaging Needs

-

Innovative Tube Boxes Revolutionizing Packaging Solutions for Sustainable Industries

-

Top 10 Benefits of Container Packaging for Product Safety and Efficiency

-

Top 10 Small Plastic Containers for Organizing Your Home and Office

-

7 Best Plastic Clamshell Containers for Global Buyers in 2023

-

5 Essential Tips for Choosing the Right Clear Plastic Tube for Your Project