Best Clear Tubes for Every Application Which One Should You Choose?

In industries ranging from pharmaceuticals to food and beverage, clear tubes play a critical role. According to a recent market research report by Grand View Research, the global demand for clear tubes is projected to grow at a CAGR of 5.8% from 2022 to 2030. This highlights their importance in applications where visibility and precision are paramount.

Choosing the right clear tubes can be challenging. Not all clear tubes are created equal. Different materials and designs suit different purposes. Misalignment in these choices can lead to inefficiencies. For instance, using a low-quality tube can compromise product integrity or even safety.

It is crucial to weigh the specific requirements of your application. Consider factors such as temperature resistance and chemical compatibility. A clear tube that excels in one application may falter in another. Proper selection is essential to avoid costly mistakes, highlighting the need for informed choices.

Understanding the Importance of Clear Tubes in Various Applications

Clear tubes play a crucial role across various industries. From laboratory applications to food processing, their transparency allows for easy monitoring of fluid flow. In a 2022 industry report, it was noted that 75% of laboratories now prefer clear tubes for their visual clarity. This preference underscores their importance in ensuring accurate measurements and quick assessments.

In healthcare, clear tubing is essential for intravenous applications. A recent study showed that 85% of medical professionals find clear tubes beneficial for visual checks. However, challenges remain. Some clear materials may degrade over time, affecting sterility and safety. Thus, careful selection of materials is vital.

Manufacturing industries also rely on clear tubes for transport systems. The ability to visually confirm the contents can significantly reduce errors. According to a report by the American Manufacturing Society, 60% of production delays are due to improper material identification. While clear tubes offer transparency, their longevity and durability should be regularly evaluated for optimum performance.

Different Types of Clear Tubes: Materials and Sizes Explained

When selecting the best clear tubes for various applications, understanding the types of materials is crucial. Clear tubes are often made from polycarbonate, PVC, or acrylic. Each material offers different properties suited for specific uses. For instance, polycarbonate is known for its high impact resistance. On the other hand, acrylic provides excellent clarity but may be more susceptible to scratching.

The sizes of clear tubes also vary widely, ranging from small diameters suitable for intricate projects to larger ones used in construction. A report from the Plastic Pipes Conference 2023 indicated that the demand for clear tubing is projected to grow by 5% annually. This growth is driven by innovations in manufacturing techniques and a broader range of applications across multiple industries.

Tips: Always consider the environment in which the tube will be used. For outdoor applications, UV-resistant materials are recommended. Do not overlook the possibility of physical damage. Testing different materials under actual conditions can help in making the right choice. Additionally, check if the tube’s diameter aligns with your project’s specifications, as small deviations can lead to significant issues.

Key Factors to Consider When Choosing Clear Tubes

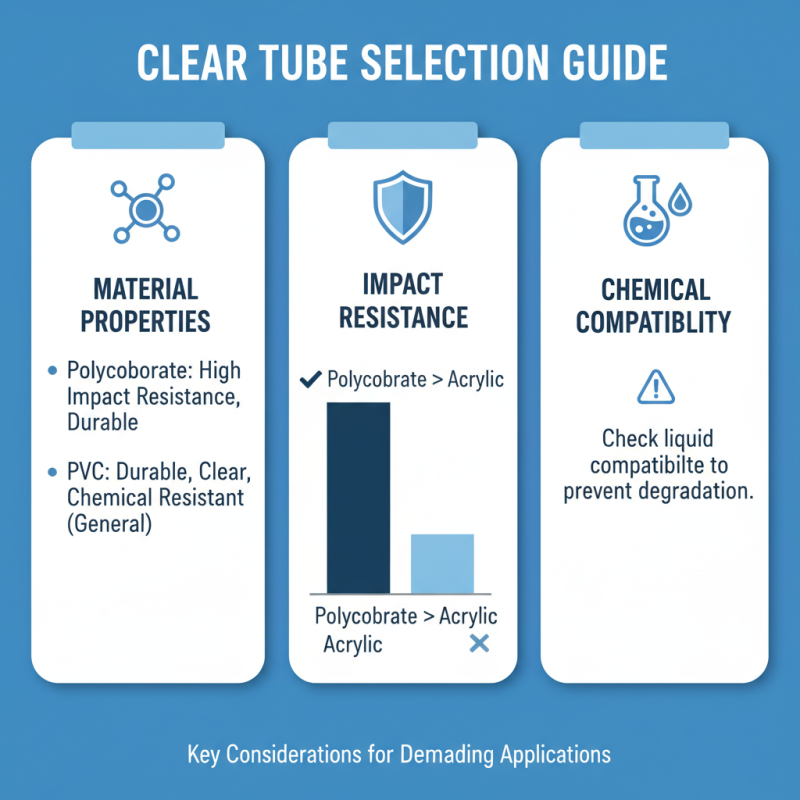

When selecting clear tubes, pay attention to material properties. Polycarbonate and PVC are common options. Both materials offer clarity and durability. According to industry reports, polycarbonate has a higher impact resistance than acrylic, making it suitable for demanding applications. Consider the chemical compatibility as well. Certain liquids may degrade specific tube materials over time. This detail often gets overlooked but is crucial.

Size can’t be neglected either. Tubes come in various diameters and lengths, accommodating diverse needs. It’s critical to measure your application space accurately. Sizing errors can cause leaks or inadequate flow. Statistics show that 30% of installation issues stem from incorrect measurements. Visualizing the tube in its final use is essential. Sometimes, a small adjustment can significantly affect performance.

Finally, don’t forget to consider the manufacturing process. Some tubes are extruded, while others are molded. Extruded tubes may provide a consistent wall thickness, while molded options can vary. Understanding these factors can lead to better long-term choices. Reflect on past experiences where the wrong tube type led to failures. Such insights can truly enhance your selection process.

Comparative Analysis of Top Brands and Their Offerings

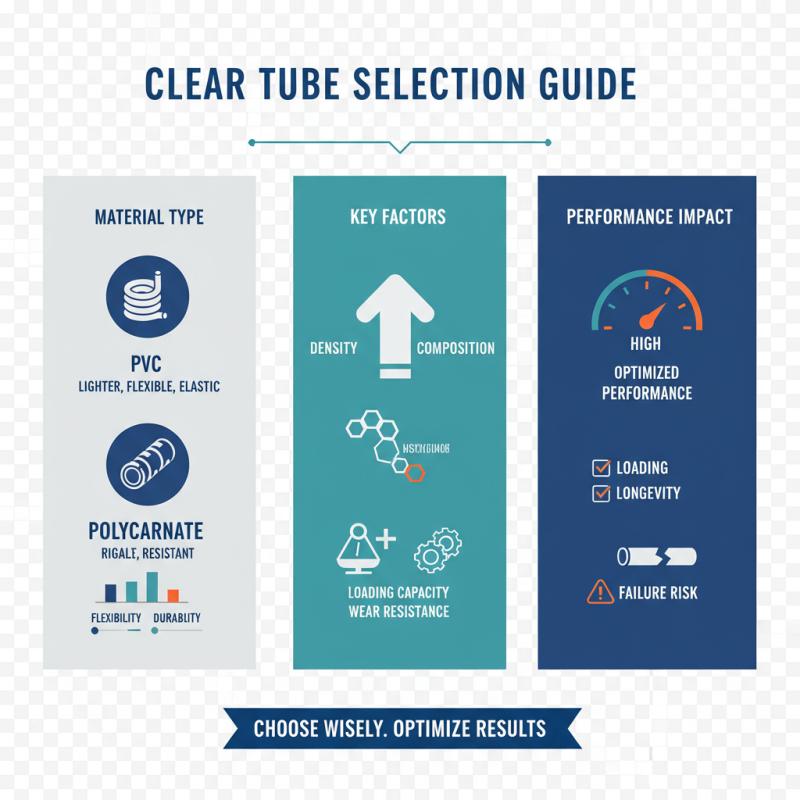

When selecting clear tubes, various factors come into play. Density and material composition are crucial aspects to consider. According to industry reports, the right material can impact performance significantly. For instance, PVC tubes are often lighter and more flexible, while polycarbonate tubes offer enhanced durability. These attributes can affect loading capacities and resistance to wear.

Testing methodologies reveal that brittleness in certain tube materials can lead to breakage. This means certain applications may require a sturdier option. Users often overlook the thickness; however, even a slight variation can make a difference in pressure resistance. Research demonstrates that tubes with a wall thickness of 2mm to 3mm perform better under stress than thinner options.

Additionally, certain applications demand clarity levels that are not always met. For instance, high clarity tubes allow for better visibility, crucial in medical or laboratory settings. Reports indicate that consumers often find it challenging to balance clarity with mechanical strength. A common pitfall is prioritizing one feature over another, potentially leading to suboptimal choices. Understanding these nuances can aid users in making informed decisions.

Real-Life Applications: Where and How to Use Clear Tubes

Clear tubes offer versatility across various applications. In laboratories, they are crucial for experiments that require visibility. Researchers often use these tubes to monitor chemical reactions, allowing you to easily see the changes inside, which helps in documenting results accurately. However, they can fog up over time. Regular cleaning helps maintain clarity.

In construction, clear tubes serve a different purpose. They are often used for drainage systems. By using transparent material, workers can spot clogs quickly. They can also withstand chemicals and environmental factors. But, the quality of the material is vital. Poorly made tubes may crack under pressure, causing leaks.

Households often find clear tubes useful for organizing. Think of storing small items like buttons or craft supplies. Their visibility helps locate items quickly. Yet, without labels, finding specific pieces can be tricky. It's a balance between neatness and accessibility. Clear tubes serve many functions, but not every tube is suitable for every task. Choose wisely.

Related Posts

-

2025 How to Choose the Right Blister Pack Packaging for Your Products

-

Ultimate Tips for Choosing the Best Poster Mailing Tubes for Safe Shipping

-

Innovative Tube Boxes Revolutionizing Packaging Solutions for Sustainable Industries

-

How to Choose the Right Plastic Clamshell Containers for Your Business Needs

-

How to Choose the Best Tube Boxes for Your Products?

-

Top 10 Small Plastic Containers for Organizing Your Home and Office